Heian NC-142 PMC 1813W Twin Table CNC Router

Japanese twin table CNC router. These machines are exceptionally well built. The ball screws typically can be rebuilt many times before they fully wear out. Ballscrew Guys likes working on these, as they are stoutly constructed. The NSK ball screw and linear motion rails are some of the best in the industry. Ballscrew Guys have rebuilt and refurbished a great many of these motion systems components. We can save your facility downtime and funds by refurbishing the ball screw that you already have.

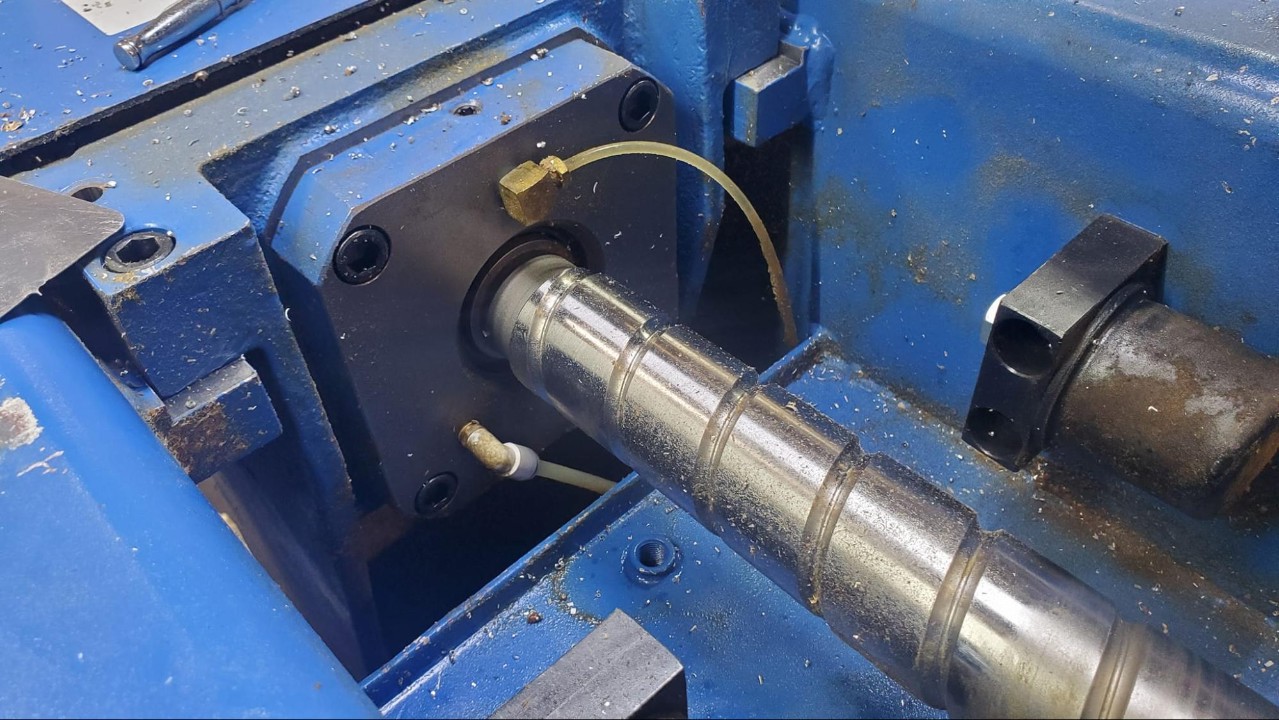

Ballscrew Guys servicing one of the table ball screws on a Heian NC-142 PMC 1813W Twin Table CNC Router. Shown is the servo motor side end bearing assembly. Notice the ball screw shaft fits into the housing. The seal is intact. Also note the independent lubrication line going into the bearing housing flange. One of the reasons why Heian are so pleasant to work on is because such care has gone into making sure critical bearing systems receive lubricant. The ball screw shown is typical of an NSK type shaft.

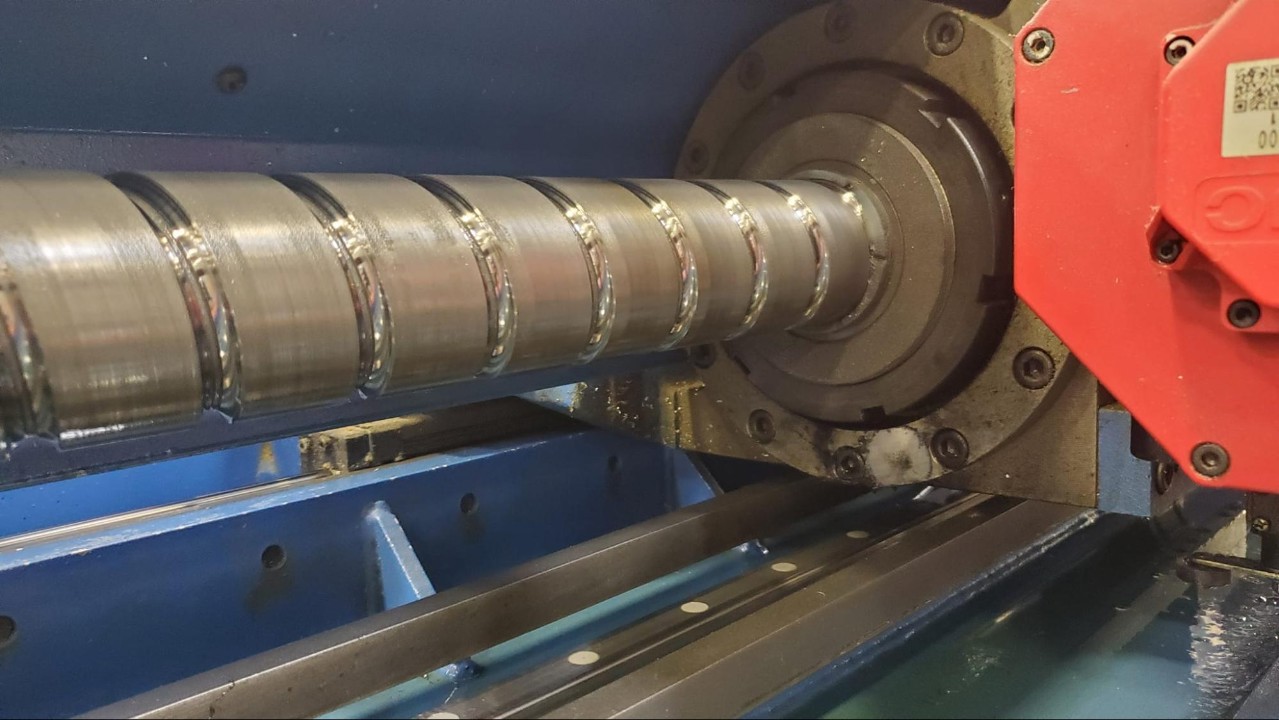

Here Ballscrew Guys is showing an image of the bridge ball screw as found on a Heian NC-142 PMC 1813W Twin Table CNC Router. Here the ball nut has an external rotation bearing system and works on a pulley drive. Next to the ball screw assembly is a FANUC servo drive. If you look at the film or discoloration on the ball screw shaft, you can see that the ball screw is dry, needing lubrication. The two single greatest reasons Ballscrew Guys have to rebuild screws are time (machine hours) and interruption of the lubrication system. The thing is, you can repair the lubrication system later on. But this does not address or correct existing damage done to your motion system components when the lube flow was interrupted.